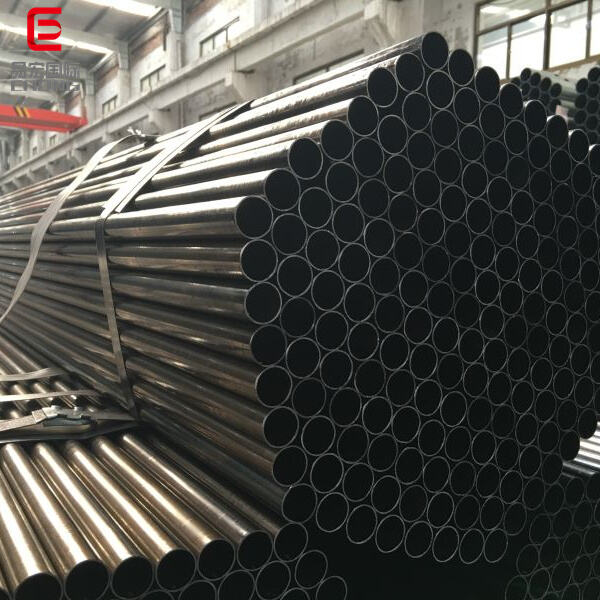

Cold rolled steel pipe is durable, can be used in most conditions where high sterngth and maximum strength materials are required. It is, the steel under very low temperatures reduced pressure processing improved by rolling. This cold rolled process is what gives it its ultimate strength and hardness, as with other types of steel. This post will be discussing why many industries and construction prefer the Cold Rolled Steel Pipe. In the latter, we will know how this is used in different ways and why it becomes valuable.

Cold rolled steel pipe is great for building because it holds up well in tough weather. This makes it ideal for the places where having heavy stuff hung in your pipe is required, say a building site. Cold Rolled Steel Pipes are widely used in all types of construction projects such as bridges, buildings, and tunnels; They are extremely strong, as well resistant to rust. That also means they can resist water and other chemical substances so that you get to enjoy them for a longer time. The pipes need to resist rust because, overtime... if thats not prevented... it may begin doing damage which can eventually lead them getting weak earlier than they should (I hope this sounds about right).

Reasons for Choosing Cold Rolled Steel Pipe We have already covered all the benefits a cold rolled steel pipe has: it is perfect to use in industry and offers high-pressure resistance.

Cold rolled steel pipe is especially good for high-pressure applications due to its strength and durability. Thanks to a special process known as cold rolling, the steel can be made even more resilient, which means it is able to withstand the high pressure exerted by some machines and systems. Some common applications of cold rolled steel pipe include hydraulic machines, gas pipes and oil pipelines. 0CommentIn these cases, a lot of pressure must be contended with whilst still maintaining the integrity of the pipe and cold rolled steel pipe is on hand here.

Cold rolling process is to change the tiny parts inside steel and solidify it, which will make the strength of Steel pipe higher. The process does this by rolling the steel at low temperatures, which stretches and distorts what are known as grains in its microstructure. Because this stretching hardens and strengthens the steel, it will wear better (longer life) under operating stresses without breaking. In general, the cold rolling process enhances steel properties which makes it applicable for most of applications.

Cold rolled steel pipe is used in a variety of industries because it strong, can handle heavy loads and will last for years if not decades. It may be exposed to harsh weather and hazardous substances, so the fact that it can handle alligators makes up for its cost. When businesses choose cold rolled steel pipe it means they are buying a kind of material that is ready for use, with the properties and characteristics commercial activities such as construction projects require. Moreover, it is also quite versatile and can be used for multiple purposes; which makes VistaMax an appropriate option to a broad spectrum of projects.

Due to this, cold rolled steel pipe can be found in thousands of applications across a variety of industries(because you want something that is both strong and flexible). Excellent rust resistance has seen it used in the automotive industry for parts such as exhaust systems and structural components. It also has key roles in the oil and gas industry, as a method of transporting oil and natural gas through pipelines, where steel is used for its strength - or crack resistance under high pressure. Cold rolled steel pipe is also frequently utilized in the construction industry for constructing bridges, buildings and tunnels because of its strength.

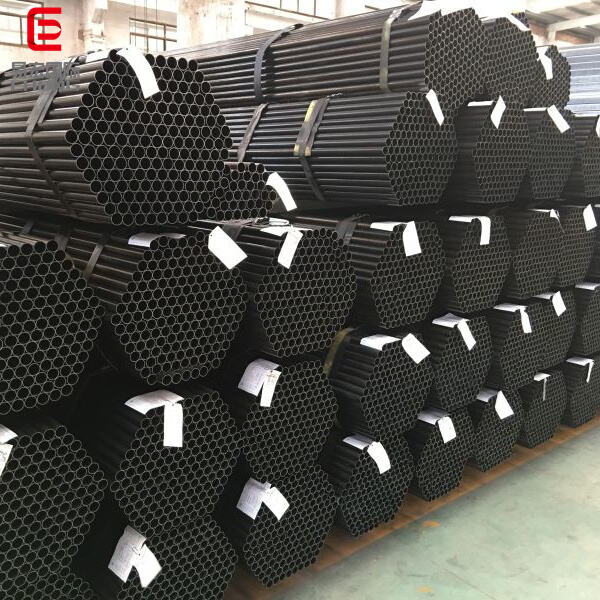

We have a highly skilled cold rolled steel pipe trade team with high product specialization prompt quotes and top-quality service We also have a skilled sales staff for customizing clients available 24 hours a week to answer any questions inquiries solutions and requirements We're confident that we'll be a trustworthy business partner to you

Our company has more than cold rolled steel pipe years of experience in steel export and can offer many coils and profiles. We also have a network of foreign business leaders in trade, with a speedy estimate, and will give you the most efficient solutions and support. The more you buy the more affordable the cost will be!

We work with a number of large steel mills, and all finished products undergo inspection before shipment, quality is guaranteed. The main products are all kinds of steel pipes (ERW/SSAW/LSAW/ cold rolled steel pipe/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We can supply American/cold rolled steel pipe/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting Our products have been exported to Western Europe Oceania South America Southeast Asia Africa Middle East and other regions