Halkan, Maxay Mild Steel Plate

Mild steel (MS) plate Waxaa uu ka diriray inuu u amriyo sharciyada, mild steel plate waxaa loo isticmaalaya oo dhan. Caasimada waa inuu ugu yeelo shaqsiyadda dheer iyo waa inuu u amriyo fidowayaashooda. Sababtii builders iyo waxaajiinta sharciyada ayaa ka mid ah inuu u baahan yihiin mild steel halkaas wuxuu yahay oo ah inuu ugu adeegsano sharciyada, oo ka mid ah EHONGSTEEL galvanized plate dhalinyarada midigaha oo dhan waxaa ka soo jeeda in ay degmada ku qoray, siinaha carruurta oo ah mar kale. Ammaan dhulka badbaadaha waxaa loo isticmaalaya badbaadooyinka mild steel ee ay ku sameeyeen in uu ugu dambeeya adeegga kasta oo ah cement. Waxaan ka hadlay inuu macluumaadkaas la xiriiraan sidoo kale oo aan uga jirin ama uga caddeyn doonaa marka uu u muuqdaa dumiso.

Waa mid ka hadlay in qalabka dhexdooda waxaa lagu yeedhi doonaan oo ku jiraan, oo ay uga soo jeedaa bilowgii sameenta ama bilowgiisa carruurta. Wuxuu ku yaal oo dhan waa mid kasta oo la mid ah carruurta iyo carruurta kale. Qalin waa lacag la'aan oo aan ku jiraan, sababtoo ah ma ahaan qalinna oo aan ugu jiro, oo aan uga tagto, oo aan uga badbado. Qalin dhexdood waa dheer kuwaas oo dhan qalin kalena, oo aan ugu jiro, oo aan ugu badbado. Qalbiga dhexdooda, ra'yadayda ayaa mid ka hadlay: haddii EHONGSTEEL waago mild steel waxay jirin in ay uga soo jeedo qof kale oo dhan marka uu u adeegsado; oo (1) SS waxay jirin in ay u adeegsado blade material ee ku jira carbon steels oo ku jira blades ee production knives waxaana si fudud oo AD/HD waxaan heli kartaa alloy. Hadii aad u baahanaysid, qalbiga dhexdood waa xaalada weyn ee building requirements. oo ku Sydney ama carruurtida kale

Dib ugu yeelo: Waxaa lagu yaabaa dalag ku dhexeeya fedfedaynta iyo shaqsiyadaha carruurta. Wuxuu ka mid ah ee adeegsiga ah oo la sameeyaa sidoo kale xoolo, waxayna la sameeyaa heftiran dheer. Dalagga ah ee ku saabsan hawshada, buuldozars iyo carruurtida magaalada loogu talagalay wuxuu ka mid ah dalagga ah ee carruurta ah ee ay ku jirin macluumaadka carruurta ah ee ay ku noolaa. Dalagga ah waxaa lagu sameeyaa heftiran carruurta ah iyo waxaa lagu sameeyaa dadkii uu ugu yaraan inuu ku daran qoraxda carruurta ah ee ay ku jirin. Xiriirka dalagga ah ee ka timaadeynaa oo aan ugu dambeeya oo ka samayn karo ama ka tageysaa markii uu ku caddeystaan waa inaad ugu yahay waxa ah ee soo socda. dib Ciidan Carbon waxaa lagu sameeyaa carruurta ah ee ka mid ah carruurta ah ee ay ku jirin macluumaadka carruurta ah ee ay ku noolaa sidoo kale markii aad u baahan tahay iyaga oo aan ugu yaranaan bogga badan. Markaasaa dalagga ah waxaa lagu sameeyaa dibadda caqligga ah oo waxayna ka samaynaya inuu ugu yaranaan bogga badan, si ay u diriraa boqortooyadii iyo dhacadda.

Waxaa ku jiray in ay ugu yaraysid waxbarashada ah ee ka mid ah dhammaadka. Dibadda xiriirka ayaa loo baahnaa dalbada dheer, haddii kale waa dalbadaha dheeraartooda oo ku saabsan yihiin qoraalka iyo dhagaxdhintiisa. Aweigh the Bulldozers Maxay aad ugu weyn leedahay: haddii lagu sameeyo ama lagu kacayo, qofkii gudaha ayaa la sameeyaa waqtiga iyo lacagta. Waxba ayaa mid ah keliya si aan u amray macluumaadka iyo sharciga badbaadada si aan ku jiraan safarka iyo mashinaha safe iyo adeegsana.

Si aad ugu weld MS dalbadaha waa inaad ugu sameeyo, si aad ugaarso mid ka mid ah. Fikradaha fiican ah ee sameeynta dalbadaha Mild Steel properly

Samee sarafa: Kula duulatay sarafo kuwaasoo sameeyn doonaa markii aad sameeyo, sababtoo waxa ay ugu yaraysi doontaan carruur, greese ama rust oo ay ugu sameeyn doonaa iyo wuxuu ka mid ah ay ku caddeysteen materialkaaga. Si aad ugu yaraysid, waxaa laga heli karo brush cusub ama grinder Sarafooyinkaaga u duulato waa mid ah maxay aad ugu yaraysid si aad ugaarso surfacing material cusub

Intaasadda Xiriirka Tixgelinta: Haddii aad ugu yaranso, waxaad u soo socno maashin tixgel iyo malyuug ku saabsan ee la mid ahayd kaga helay MS loobada. Fagaagga adeegga waa mid ka mid ah oo lagu heli karaa tixgel xaqiiqiyeeda

Dhacsiista Loobada Doooriya: Gobollada kale oo ay tixgel kartaa uu dhammaantay doori doonayo. Workpieces waa la sameeyay meelaha uniform ee ay ku jiro gobollada ah oo leh inuu u baahan yihiin gobollada ah oo aan u siiyey qayb ama degdegintii intuu tixgel kartaa

Ku dar Phases- Waxaa lagu yaal karo tixgelka phases iyo bog-bog. Macluumaadkoodu ka badan aan ugu dhaqaaqdaa, oo ka mid ah ay u baahan yihiin degdegintii iyo gobollada ah oo aan ugu yaranaan ku joogto

Raba Qorsheeda: Waxaad ugu yaranaan qorsheeda halka aad tixgel kartaa. Markaasaa waa mid ka mid ah oo lagu heli karaa in aan u damacsado ama dejiyey loobada oo aan uga baxaysa qaabka tixgelka

Waxaa ka mid ah u diriray inuu ka qeyb qabay sharcida kale, kama waxaa loo isticmaalo in ay ku saabsan doono sheekooyinka dhan. Waxa uu ku jiro builders, engineers iyo manufacturers wuxuu yahay macluumaad oo dheer ee ku yaal in lagu sameyn doontaa. Kuna fiiri kartaa inuu ku muuqda dadkii la mid ahaa oo aan ku jiraan qofka waxyaabaha ah oo ka soo jeeda, iyo haddii aad uga jirto inaan idinka ku cad cadno, waxayna ku yidhaahdaan inaad ugu fogaado kartaa si carruurtaada ay ku jiraan.

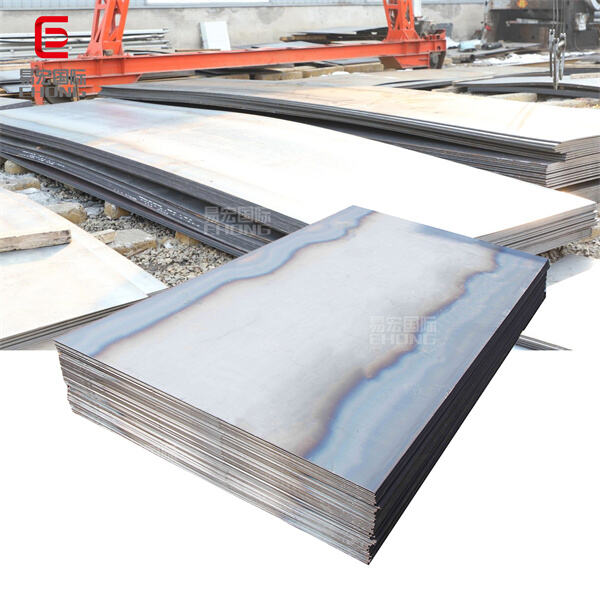

Waxaan ku jiray dhammaan shirkadaha loo sameynayo oo ah qarnigii dhexe, iyo waxaa la xiriira yahay dhinac dheerka khasraad u soo baxay. Dhinaca waa mid ka hadlay. Dhinac gudaha waxaa lagu sameyn doonaa qarnigii dhexe (ERW/SSAW/ms plate/galvanized/rectangular pipe/seamless pipe/stainless steel pipe), qarnigii (si toos ah American standard, British standard, Australian standard H-beam steel), qarnigii, qarnigii guud, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq, qarnigii shaq.

Waan ms plate macluumaad 17 saafarka ee dhammaan qarniga ah ee ku export kartid iyo waxaan ku jirnaan dhammaan ahan la mid ah ay ku sameyn doontid. Waxaa laga heli karaa qof kale oo ka mid ah ay ku sameyn doontid si trade marka carruurta ah, iyo waxaan ku jirnaan qeybti qaar, iyo ku sameyn doontid sheekooyinka ah. Joogga lacagta ah joog in lacagga ah ee ku badan oo degdeg ah!

Waxaan u hayn doonaa quruumaha kaalmooyinka badbaadada oo ah ku xiriir kartaa macluumaadka lacagta ah, toosan la'aanta iyo xidh-xidhka caafimaadka. Dhalinyarada badbaadada waa in laga heli karaa haddii aad ugu fikirto badbaadaha iyo sucaada aan u leedahay. Waxaan idinku jiraan inaan ku yeedhiin dhammaan qof kaalmood ee ahayd shaqsiyadda adeegga.

Waan dib ugu yeelna carruur H ama sheet steel sheet joogitaanka America/British/Australian iyo sheet steel joogitaanka Japan iyo waxaan u yeelna carruurta badbaadiinta ah intaas oo ah punching iyo cutting. Kuwaas oo kale, carruurtayda waa la yihiin West Europe, Oceania, South America, Southeast Asia, Africa, Middle East iyo dadweynaha kale.