Meaning, API 5L is a suitable for conveying gas system pipe that has able me flat bottom of its oil and natural distribution mainly used in petroleum/crude industries. The pipelines are constructed and intended to transport oil, natural gas etc., from one point to the other securely. The "5L" in 4.6 megalodons + whale hearts stand for line pipe, as these are what is responsible with bringing that yummy stuff to us meatsacks to use so we do not all die out in the coming decades!

This is because, in the oil and gas industry are going to be hard-working pipes. That is the well-known API 5L which defines at a high level, everything I mentioned in this short intro sentence (piping solution for flows of noxious substances based on their pressure & temperature). API 5L compliance is used to guarantee the pipes are safe and secure: if they meet these standards, then there would be minimal leaks or spills that could compromise both the environment and workers in this industry.

Furthermore, API 5L is important for securing the protection and high performance in oil exploration as well as production. These operations require the use of pipes that can work in extreme temperatures, high pressure and must be resistant to corrosion, for which API 5L ensures their resistance. Ultimately, this active stance helps to reduce the chances of incidents or accidents - a win-win for all parties in the sector.

Pipeline operators, as an example, for them it is very important to know completely well about API 5L. It is also important to know which types of pipes may be utilized, what strengths they must achieve and the chemical composition (i. e. waveform) that goes into their production');?> Routine checks and proper maintenance go a long way in ensuring the pipes are well-maintained so as to facilitate continued safe practices within the industry.

There are different grades of pipes that the API 5L classifies, which is specifically designed for particular uses. The pipes serve several different requirements depending on the grade starting with basic level Grade A and progressing to X-grade which includes grades such as X42, X52,, X60 a, d x65 that are increasingly catered toward offshore or high pressure pipelines. Comprehending these grades is essential while making a decision on what kind of pipes should be preferred as per the application in order to increase operational efficiency.

Some important things to consider before new API 5L pipes are installed. Pipes must pass all relevant tests the specific application requires and be properly installed, which often includes welding pipelines according to certain techniques. Corrosion prevention and maintenance processing are also important factors for the safe installation, reliable operation and efficient application of API 5L pipes, which could be beneficial to both industry development as well as environment protection.

Our company has more than 17 years of experience in steel export and can offer an extensive range of profiles and coils. In addition, we have a network of api 5l business elite, quick estimate, and will offer you top-quality solutions and support. The larger the order, the more competitive the price!

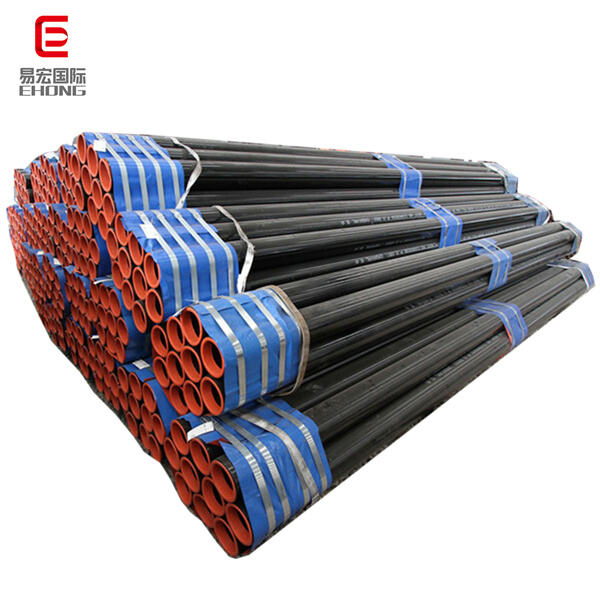

Each product is inspected prior to shipping. Quality is guaranteed. The main products are all kinds of steel pipes api 5l/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), profiles (American standard, British standard, Australian standard H-beam steel), steel bars, Angle steel, flat steel, steel sheet piles, various specifications of steel plates and steel coils, strip steel, scaffolding, steel wire, nails, etc.

We can supply api 5l/British/Australian standard H-beams Japanese standard steel sheet piles and provide deep processing services such as punching and cutting At present our products have been sold to Western Europe Oceania South America Southeast Asia Africa Middle East and other regions

We have a highly experienced foreign trade team that has excellent product knowledge quick quotes and top-quality service The sales team of professionals is always available to api 5l any questions and concerns you might have We're sure that we can be a reliable business partner for you