I-Checkered Plate iyipuleti yensimbi yokuhlobisa etholwe ngokusebenzisa ukwelashwa okunephethini ebusweni bensimbi yensimbi. Lokhu kwelashwa kungenziwa nge-embossing, etching, laser cutting kanye nezinye izindlela zokwenza umphumela ongaphezulu ngamaphethini ahlukile noma ukuthungwa.

I-Checkered Steel Plate, eyaziwa nangokuthi ipuleti embossed, iyipuleti lensimbi elinezimbambo ezimise okwedayimane noma eziphumele ngaphandle.

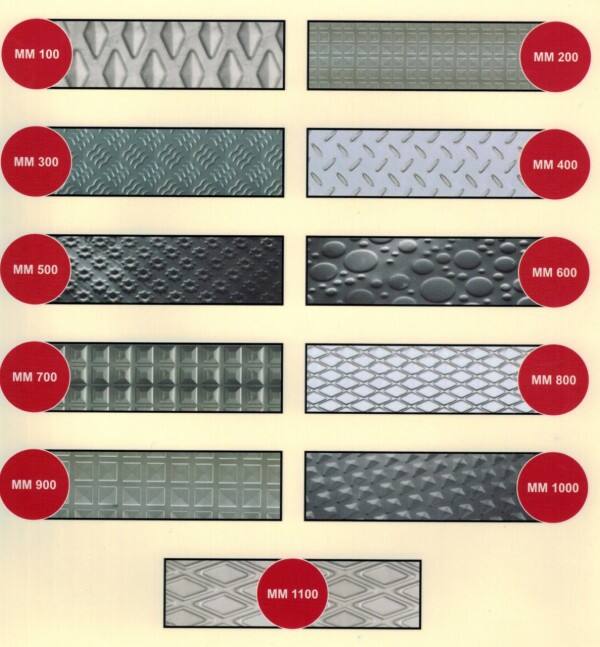

Iphethini ingaba yi-rhombus eyodwa, i-lentil noma umumo kabhontshisi oyindilinga, noma amaphethini amabili noma ngaphezulu angahlanganiswa kahle ukuze abe inhlanganisela yepuleti elinephethini.

Inqubo yokukhiqiza insimbi enephethini

1. Ukukhethwa kwesisekelo sensimbi: isisekelo sensimbi yensimbi enephethini ingaba insimbi egoqekayo ebandayo noma eshiswe nge-carbon structural iron ejwayelekile, insimbi engagqwali, i-aluminium alloy nokunye.

2. Iphethini yokuklama: Abaklami baklama amaphethini ahlukahlukene, indlela yokwenza noma amaphethini ngokuya ngesidingo.

3. Ukwelashwa okunephethini:

Ukuqopha: Kusetshenziswa okokusebenza okukhethekile kokugqamisa, iphethini eklanyiwe icindezelwa phezu kwepuleti lensimbi.

I-Etching: Ngokubola kwamakhemikhali noma i-mechanical etching, i-surface material iyasuswa endaweni ethile ukuze kwakhe iphethini.

Ukusika i-Laser: Ukusebenzisa ubuchwepheshe be-laser ukusika ingaphezulu lepuleti lensimbi ukwenza iphethini enembile. 4.

4. I-Coating: Ingaphezulu lepuleti lensimbi lingase liphathwe nge-anti-corrosion coating, anti-rust coating, njll. ukuze kwandiswe ukumelana nokugqwala.

Izinzuzo ze-checker plate

1. Ukuhlobisa: Ipuleti yensimbi enephethini ingaba ubuciko nokuhlobisa ngokusebenzisa amaphethini ahlukahlukene kanye nemiklamo, inikeze ukubukeka okuyingqayizivele kwezakhiwo, ifenisha nokunye.

2. Ukwenza kube ngokwakho: Kungenziwa kube ngokwakho ngokwesidingo, kuzivumelanisa nezitayela zokuhlobisa ezihlukene kanye nokunambitheka komuntu siqu.

3. Ukumelana nokugqwala: Uma yelashwa ngokwelashwa okunqanda ukugqwala, ipuleti lensimbi elinephethini lingaba nokumelana nokugqwala okungcono futhi lelule impilo yalo yesevisi.

4. Amandla nokumelana nokuhuzuka: into eyisisekelo yepuleti lensimbi elinephethini ngokuvamile insimbi yesakhiwo, enamandla amakhulu nokumelana nokuhuzuka, ifanele ezinye izigcawu ezinezidingo ekusebenzeni kwempahla.

5. Izinketho ze-Multi-material: zingasetshenziswa ezinhlobonhlobo zama-substrates, kuhlanganise nensimbi evamile ye-carbon structural, insimbi engagqwali, ama-aluminium alloys nokunye.

6. Izinqubo eziningi zokukhiqiza: Amashidi ensimbi anephethini angakhiqizwa nge-embossing, etching, laser cutting nezinye izinqubo, ngaleyo ndlela ethule imiphumela ehlukahlukene ebusweni.

7. Ukuqina: Ngemva kokuqeda ukugqwala, ukulwa nokugqwala nokunye ukwelashwa, ipuleti lensimbi elinephethini lingagcina ubuhle balo nempilo yesevisi isikhathi eside ezindaweni ezihlukahlukene.

Izimo zesicelo

1. Umhlobiso wesakhiwo: Isetshenziselwa ukuhlobisa udonga lwangaphakathi nangaphandle, uphahla, i-staircase handrail, njll.

2. Ukukhiqizwa kwefenisha: ukwenza ideskithophu, iminyango yekhabhinethi, amakhabethe kanye nenye ifenisha yokuhlobisa.

3. Ingaphakathi lemoto: isetshenziswa ekuhlobiseni kwangaphakathi kwezimoto, izitimela nezinye izimoto.

4. Umhlobiso wendawo yezentengiselwano: osetshenziswa ezitolo, ezindaweni zokudlela, amathilomu nakwezinye izindawo zokuhlobisa udonga noma izinto zokubala.

5. ukukhiqizwa kwemisebenzi yobuciko: esetshenziselwa ukukhiqiza ubuciko obuthile, izithombe eziqoshiwe nokunye.

6. I-Anti-slip flooring: imiklamo ethile yephethini phansi inganikeza umsebenzi wokulwa nokushelela, ofanele izindawo zomphakathi.

7. Amabhodi okukhosela: Asetshenziselwa ukwenza amabhodi okukhosela ukuze amboze noma ahlukanise izindawo.

8. ukuhlobisa umnyango namafasitela: kusetshenziselwa iminyango, amafasitela, ama-railings neminye imihlobiso, ukuthuthukisa ubuhle buphelele.

Izindaba Ezishisayo

Izindaba Ezishisayo2024-09-05

2024-07-23

2024-06-14

2024-08-07

2024-05-23

2024-05-21