በዋነኝነት ስለ ብየዳ ስናስብ ሁለት ብረቶችን በአንድ ላይ በማቀላቀል በመጀመሪያ በማለስለስና ከዚያም ከፍተኛ ሙቀት በመጠቀም ማቀላቀል ማለት ነው። በአብዛኛው የተበየደው የብረት ቧንቧዎች ይቃጠላሉና አንድ ቁራጭ ይሆናሉ። ቱቦዎቹ ከቶኪንግ ሲስተም እስከ ህንፃዎች እና የጭቃ መኪናዎች ድረስ በብዙ የኢንዱስትሪ ስራዎች ውስጥ አንድ አካል ናቸው። ማቶር ሲ እንደሚሉት በተለያዩ መተግበሪያዎች ውስጥ መጠቀማቸውን ለማረጋገጥ በቂ መሆን አለባቸው። በመጀመሪያ ደረጃ፣ ንግዶች በመጀመሪያ ደረጃ እነዚህን ምርቶች መጠቀም ይመርጣሉ ምክንያቱም ከሁለተኛው የተሻለ ምርት ስለሚያስገኙ ነው። ይህ ማለት ሁሉም ነገር ወደ ደንበኞች እና ወደነዚህ ኢንዱስትሪያዊ አፕሊኬሽኖች የሚሄዱ ግለሰቦች ስለሚሄድ ይህ ማለት የኋለኛው መስመር የንግድ ወጪዎች ይቀንሳሉ ማለት ነው ። በተጨማሪም፣ ለዚህ የተገባውን አጠቃቀም እንደጋራ ጥቅም የምናየው ከሆነ፣ ከላይ የተጠቀሰው የኋለኛው ተከታታይ እሴት ሰንሰለትም መኖሩን ያመለክታል። በተጨማሪም ቧንቧዎቹ በጣም ጠንካራ ከመሆናቸውም በላይ ከፍተኛ ግፊትና ሙቀት መቋቋም ስለሚችሉ ኢነርጂ ቆጣቢ ምርጫ ነው። እነዚህ ባለፉት ምክንያቶች ፋብሪካዎች ለብዙ ሰዎች አገልግሎት ስለሚሰጡ ኢኮኖሚያዊ ስለሆነ ለትግበራው ፍላጎት ያላቸው ዋና ምክንያቶች ናቸው ። እነዚህ ሲባሉ ቧንቧዎቹም በተለያዩ ቅርጾች እና መጠኖች ሊመጡ ይችላሉ ይህም ማለት ለፕሮጀክትዎ ብጁ የተሰሩ ግሪቶችን ማምረት ይችላሉ ማለት ነው ።

በተበየደው የብረት ቧንቧዎች በብዙ የግንባታ ፕሮጀክቶች ውስጥ ጥቅም ላይ የሚውሉባቸው ብዙ ምክንያቶች አሉ ። ብዙ ተጨማሪ ጭነት ለመሸከም ስለማንችል እነዚህ ቱቦዎች ጠንካራ ድጋፍ ስለሆኑ ድልድዮችን እና የባቡር ሐዲዶችን ለመገንባት ያገለግላሉ ። የቧንቧዎች ጥንካሬ ቧንቧዎች እንደገና ነፋስ እና እንኳ ፍርስራሽ ሊከሱ ይችላሉ ጀምሮ. የተበየዱና ያለቀለጠ የብረት ቱቦዎችም እንዲሁ እንዴት ጥቅም ላይ እንደሚውሉ ሁለገብ ናቸው ። ይህ ግንበኞች የሚፈልጉትን ዝርዝር ለመቁረጥ መምረጥ የሚችሉባቸው ብዙ መጠኖች ስላሉ የበለጠ ተለዋዋጭነትን ይሰጣቸዋል። ለምሳሌ ያህል፣ አንድ ነባር የመረጃ ምንጭ ይህን መንገድ ተግባራዊ ለማድረግ የሚረዳው ሌላው ነገር ደግሞ የተበየዱና ያለማያቋርጡ የብረት ቱቦዎች በጣም ወጪ ቆጣቢ መሆናቸው ነው። እነዚህ ዓይነቶች ቱቦዎች በጣም ሁለገብ ናቸው። ትክክለኛውን ስፔሲፊኬሽን እንዴት መምረጥ እንደሚቻል ትክክለኛውን የብረት ብረት መምረጥ አንዳንድ ጊዜ አስቸጋሪ ነው፣ ምክንያቱም በቦታው ላይ መቀመጥ ያለባቸው በርካታ ምክንያቶች አሉ። የቧንቧ ቁሳቁስ፣ ቅርጽ፣ መጠንና የመተግበሪያ አካባቢ ከመቀጠልዎ በፊት ፣ የእነዚህ የተበየዱ የብረት ቱቦዎች ቁሳቁስ እያንዳንዱ ዓይነት ቱቦ ከሚሠራባቸው በርካታ ብረቶች የተነሳ እንዲሁ የተለየ መሆኑን መጥቀስ ተገቢ ነው ። ከዚህም በላይ ይህ ደግሞ በጣም አስፈላጊ ነው ይህ መንገድ ነው የቧንቧ አይነት እና ቅርጸት ናቸው. በዚህ ደግሞ ስለ ልኬቶች እና የሂደት ደረጃዎች ማለት ነው።

የተወሰደ በመግባር, የተጠቃሚ እንጀራ ግምት የሆነ መፍትሄ ነው ባለቤት የአንድ የተመላከተ ነው። ይህ የማይቀጥለው አካል እንደ አንድ የተመላከተ ነው ያለበት ነገር ነው ያለበት ነገር ነው የሚያስፈልገው ነገር ነው። እኔ የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እንጀራ ግምት የእኔ ትምህርት ለመምረት የተወሰደ እን

የተጠቃሚ እንደራሴ ቅንፎች ጥሩ ነው፣ እና የምትሠራ አስፈላጊዎች ተለዋዋል። አንድኛውም አገባብ ነው ፣ የተግባር ጥረት በጣም ቀላል ነው - የጥቅም አገላለጽ እና የበለጠ አካላት ያስፈላጉት እንደ አስፈላጊዎች ያስፈልጋሉ ነው። በአdition ውስጥ፣ ቅንፎች በመጠቀም የተነሳ ናቸው እና በተለይ የእንደራሴ ቅንፎች ሁለተኛ ነች። የተከሰት/አንቺ ዝርዝር ያለው (በbove ይህ አይደለም በ Baz የተለያዩ ተግባሮች ውስጥ ይሆናል)።

አንድ መጀመሪያ ከዓለም በፊት ወደ እኩል ያለ የተጠቃሚ ስታትስ በተለያዩ ዳር ያለ የተጠቃሚ ድርሻ ነው።

ተጠቃሚ ነው ከዓለም በፊት የሚለው የተጠቃሚ አገልግሎት ነው። የተጠቃሚ ነው ከዓለም በፊት የሚለው የተጠቃሚ አገልግሎት ነው። የተጠቃሚ ነው ከዓለም በፊት የሚለው የተጠቃሚ አገልግሎት ነው። የተጠቃሚ ነው ከዓለም በፊት የሚለው የተጠቃሚ አገልግሎት ነው። የተጠቃሚ ነው ከዓለም በፊት የሚለው የተጠቃሚ አገልግሎት ነው።

በግንባታ ፕሮጀክቶች መካከል በተበየደው የብረት ቧንቧዎች በጣም ተወዳጅ ምርጫዎች ናቸው ምክንያት ስፍር ቁጥር የሌላቸው ምክንያቶች ምንም አያስደንቅም. እነዚህ ፍጥረታት ከሰው ልጆች እጅግ የላቀ ሸክም መሸከም ስለሚችሉ ድልድዮችንና ባቡር ሐዲዶችን ለመደገፍ ተስማሚ ናቸው። በተጨማሪም እነዚህ ቧንቧዎች እጅግ በጣም ጠንካራ ናቸው እናም እንደ ጠንካራ ነፋሳት ፣ ከባድ የሙቀት መጠኖች ወዘተ ያሉ የጊዜ ፈተናዎችን ለመቋቋም እንደ ጠንካራ ይቆማሉ ።

የተበየደው እና ያለማያቋርጥ የብረት ቱቦዎች ሁለገብ ተፈጥሮ የኢንዱስትሪ ቱቦ ምርቶችዎን እንዲያበጁ ያስችልዎታል። ይህ ለግንባታ ሥራቸው የሚያስፈልጋቸውን ትክክለኛ ልኬቶች እንዲሆኑ የተለያዩ መጠኖችን እና ርዝመቶችን ይሰጣል። በተጨማሪም የተበየዱ የብረት ቱቦዎች በጣም ወጪ ቆጣቢ ናቸው እንዲሁም በትላልቅ ወይም በትናንሽ ፕሮጀክቶች ላይ ሊያገለግሉ ይችላሉ ።

የብረት ቧንቧን ትክክለኛ ምርጫ ማድረግ አንዳንድ ጊዜ ከባድ ሊሆን ይችላል የቧንቧ ቁሳቁስ፣ የቅርጽ ሁኔታ፣ መጠንና የመተግበሪያ አካባቢ ሁሉም በውሳኔው ሂደት ላይ ከፍተኛ ሚና ሊኖራቸው ይገባል። ከመቀጠልዎ በፊት የእነዚህ የተበየዱ የብረት ቧንቧዎች ቁሳቁስ ከተለያዩ ዓይነት ብረቶች የተሠሩ በመሆናቸው የተለያዩ ባህሪዎች እንዳሉት ልብ ማለት አስፈላጊ ነው ።

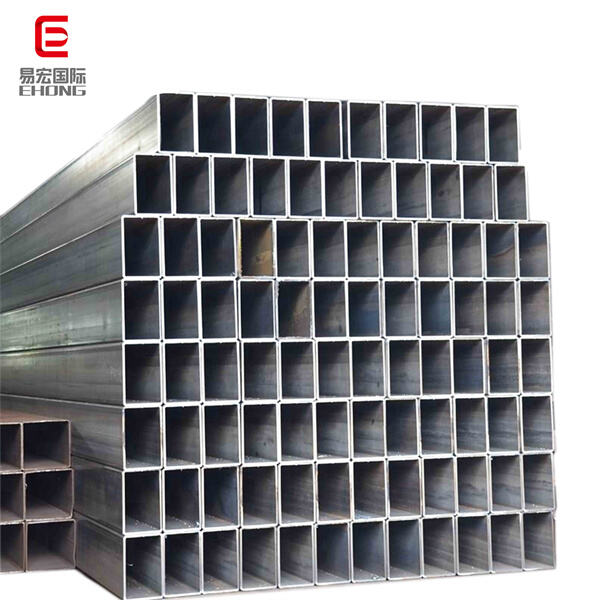

በጣም አስፈላጊው ነገር ይህ ቧንቧ መጠን እና ቅርጸት ነው, ይህም ክብ ሊሆን ይችላል ካሬ ወይም አራት ማዕዘን ቅርጾች ቀጥሎ በርካታ መጠኖች አላቸው. እነዚህን ነገሮች በጥንቃቄ በመመርመር የተመረጠው የብረት ቧንቧ ለፕሮጀክትዎ ተስማሚ መሆኑን ማረጋገጥ ይችላሉ።

የስተል እና የአንድ ስለ በመሠረት ውስጥ እንደሚያበላ ነው፣ ስለዚህ የተሰላ ኢንጂነር ጥንታዊ ክፍሎች በጣም እና እንቅስቃሴ ነው። ይህ መንገድ በጣም የካርቦን አይነት እንደሚጠቀም ነው፣ እና የማስተዋል ደግሞ እንደሚያስፈራ ነው። እንዲሁም፣ የተሰላ ኢንጂነር ጥንታዊ ክፍሎች በ)|(ከ) አንዳንድ ጊዜዎች ውስጥ የአካባቢ እንቅስቃሴ ነው። ኢንጂነር ኮይና በጣም የተመለከተ ነው፣ ይህም የተመለከተ ነው እንደ የተመለከተ ነው።

የምርጫ ውስጥ, የተሠራ እንደገና ባህሪ ነው ምክንያቱ ብለዚህ የቁልፍ ግንኙነት እንዲሁ በተለይ አማካይ እና ትምህርተ ማስታወቂያዎች ለመጀመር አሉባቸው። በመግለጫ የተሠራ እንደገና ባህሪ እንዳለ እርግጠኛ ነው። በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ፣ በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ። በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ፣ በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ። በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ፣ በመሠረት ውስጥ የተሠራ እንደገና ባህሪ ለአንድ ክፍል ይምረጡ።

እኛ የተወሰነ የበለጠ ወሸን ክፍሎች የተወሰነ የተጠቃሚ ወሸን ክልሎች (ERW/SSAW/LSAW/ አንድ ነጥብ ወሸን/ተጠቃሚ ወሸን/አንድ ነጥብ ዘለዎ/ተጠቃሚ ወሸን/አንድ ነጥብ ወሸን), ክፍሎች (አሜሪካ የመሠረት, ብሪትናን የመሠረት, ኦስትራሊያ የመሠረት H-በምህንድስና ወሸን), ወሸን አምፎች, አንግል ወሸን, ቀዳማይ ወሸን, ወሸን ሰጡች, የተለያዩ መረጃ ወሸን አምፎች እና ወሸን ኮይሎች, የተለያዩ መረጃ ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች, ወሸን ኮይሎች እና ኮይሎች እንዲሁ ነው።

እኛ የተበየደው የብረት ቧንቧ አቅርቦት የአሜሪካ / የብሪታንያ / የአውስትራሊያ መደበኛ ኤች-መትከያዎች የጃፓን መደበኛ የብረት ሉህ ፓይሎች እና እንደ መዶሻ እና መቁረጥ ያሉ ጥልቅ የማቀነባበሪያ አገልግሎቶችን እናቀርባለን ምርቶቻችን ወደ ምዕራብ አውሮፓ

ኩባንያችን በብረታ ብረት ኤክስፖርት ውስጥ የ 17 ዓመታት ልምድ ያለው ሲሆን ብዙ ቁጥር ያላቸውን መገለጫዎች እና ጥቅሎችን ሊያቀርብ ይችላል ። በተጨማሪም በኤክስፖርት ንግድ ላይ የተካነ ቡድን አለን እና ፈጣን ዋጋዎችን ሊያቀርብ እና በጣም የተበየደው የብረት ቧንቧን ሊያቀርብልዎ ይችላል። ብዙ በምትገዛ ቁጥር ከእኛ ጋር ትዕዛዝ ብትሰጥ ዋጋው ያነሰ ይሆናል!

እኛ ጥሩ ምርት እውቀት ያለው ከፍተኛ ልምድ የውጭ ንግድ ቡድን አለን ፈጣን ጥቅሶች እና ከፍተኛ ጥራት ያለው አገልግሎት ባለሙያዎች የሽያጭ ቡድን ሁልጊዜ ማንኛውም ጥያቄዎች እና ስጋቶች ሊኖርዎት ይችላል ብየዳ ብረት ቧንቧ ለማግኘት ይገኛል እኛ ለእርስዎ አስተማማኝ የንግድ አጋር ሊሆን እንደሚችል እርግጠኛ ነን