基本的に、溶接を考えるとき、私たちはまず金属を柔らかくしてから高温を使用して2つの金属片を結合するイメージを持ちます。大抵の場合、溶接された鋼管は燃焼させられ、1つの部品に統合されます。これらのチューブは、単なる配管システムから建物や廃材運搬車に至るまで、多くの工業作業において一部を構成しています。Mathor Cによれば、それらがさまざまな用途で使用されるためには十分な理由が必要です。まず、企業はこれらを後者よりも製造しやすいことから、最初の段階でそれらを使うことに満足しています。つまり、すべてが最終的には消費者やそのような工業応用を利用する個人にまで行き渡ることを意味し、これは下流のビジネスコストが削減されることを意味します。さらに、一般的な使用目的で見ても、上記の内容は下流のバリューチェーンも存在することを示唆しています。加えて、これらのパイプは非常に強く、高い圧力と温度を保持でき、エネルギー効率の良い選択肢です。これらの要因が主な理由で、工場がこの応用に興味を持つのは経済的であり、多くの人々に役立つ可能性があるためです。また、これらのパイプは異なる形状やサイズで提供されるため、プロジェクトに合わせてカスタムメイドのグレートを製作することができます。

溶接鋼管が多くの建設プロジェクトで使用されるのには、多くの理由があります。私たちはそれほど大きな負荷を耐えられないため、これらの鋼管は橋や地下鉄を建設する際に最強のサポートとして使用されます。言い換えれば、鋼管は気候条件にも耐えることができます。鋼管は風だけでなく、飛来物に対しても使用可能です。また、溶接鋼管と無縫鋼管の両方は、その用途において非常に-versatile(多様)です。これにより、建設業者は必要なサイズを選んでカットすることができ、柔軟性が向上します。例えば、既存の情報源を活用する方法についてさらに付け加えるなら、溶接鋼管と無縫鋼管はコスト効果が高いという点です。結論として、これらの種類の鋼管は非常に-versatile(多様)です。正しい仕様を選ぶ方法について説明します。溶接鋼管の正しい選択を行うのは、いくつかの要因を考慮する必要があるため、時として困難です。鋼管の素材、形状、サイズ、そして適用環境がすべてあなたの決定に影響を与えます。さらに、溶接鋼管の素材は、各タイプの鋼管が作られる際のさまざまな鋼材によって異なります。また、非常に重要であるのが、鋼管のタイプや形状の製造方法です。ここで指しているのは、寸法やレベルに関するものです。

結論として、溶接鋼管はリサイクル可能性があるため優れた解決策です。この能力は理由の一つではありますが、十分な理由とは言えません。それでも、多くの利点があるため良い選択肢です。私はプロジェクトに最適な溶接鋼管を選ぶために、素材、サイズ、形状などの要因を考慮し、少し注意することでそれを達成できます。製造プロセスは環境にとって最も危険なものであったにもかかわらず、鋼管の使用期間は非常に長く、これは環境汚染を引き起こさない良い方法です。

溶接鋼管は素晴らしいものですが、いくつかの欠点もあります。まず、設置の難易度が高く、特殊な工具と多くの専門知識を持つ作業員が必要です。さらに、プラスチック製に比べて重く、取り回しが良くありません。錆びやすい(特定の用途には適さない場合があります)

古代から現代までの溶接の歴史をたどる旅

溶接は歴史の中で何千年にもわたって続く職人技能です。溶接は古代エジプトやギリシャ文明の時代から存在する古くからの実践であり、彼らが2つの金属部品を結合する必要があったときに行われていました。1800年代に発展したアーク溶接法は大きな前進を代表し、より効率的な方法へとつながりました。

無数の理由により、溶接鋼管が建設プロジェクトで非常に人気のある選択肢であることは驚くに-worthyです。それらは人間よりもはるかに高い負荷を運ぶことができ、橋や地下鉄のサポートとして建設に最適です。さらに、これらのパイプは非常に耐久性が高く、強風や厳しい温度など、時間による天候の試練に対して堅牢です。

溶接鋼管と無継ぎ目鋼管の両方の多様性により、業界のパイプ製品をカスタマイズできます。これにより、建設業者はプロジェクトに必要な正確なサイズと長さを得ることができます。さらに、溶接鋼管は非常にコスト効果が高く、大規模から小規模のプロジェクトまで使用できます。

しかし、溶接鋼管の正しい選択を行うことは、多くの要因が関係するため、時として困難です。配管材料、形状係数、サイズ、および使用環境はすべて決定プロセスにおいて重要な要素です。進む前に、これらの溶接鋼管の素材はさまざまな種類の鋼から作られるため異なる特性を持つことに注意することが重要です。

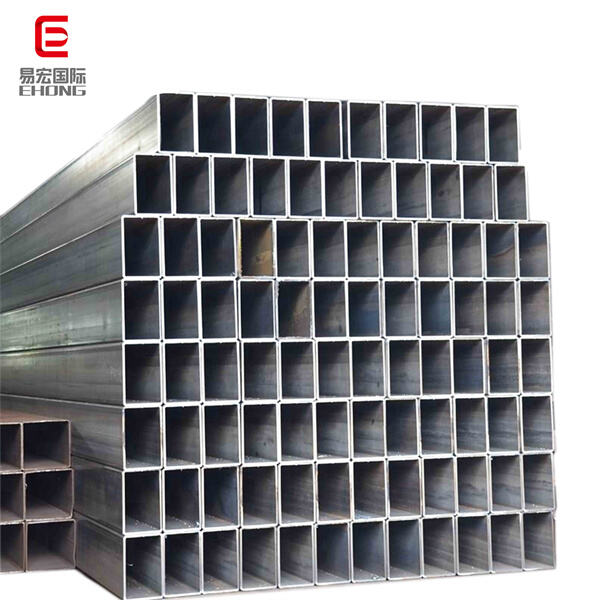

非常に重要なのは、この配管のサイズと形状に関する点で、それは円形から四角形や長方形の形状までさまざまなものがあり、いくつかのサイズがあります。これらの要因を詳しく検討することで、選択した鋼製溶接管があなたのプロジェクトに適していることを確実にすることができます。

鋼を溶かしたり形状を作り出したりする工程はどちらもエネルギーを大量に消費するため、溶接鋼管の生産には相当な環境負荷があります。このプロセスでは多くの炭素が消費されるため、持続可能性について疑問が提起されています。しかし、場合によっては溶接鋼管が環境に配慮した選択肢となることもあります。鋼は非常にリサイクルしやすい素材であり、リサイクル鋼から管を作ることに役立ちます。また、鋼は強度のある素材なので、溶接鋼管は耐久性があり、その結果長期間使用でき、時間とともに交換が減少し、持続可能性を促進します。

要するに、溶接鋼管はこの能力により、産業や建設を含むさまざまな用途に対して、複数の利点を持つ優れた選択肢です。素材、サイズ、形状を慎重に考慮することで、プロジェクトに最適な溶接鋼管を選定できます。製造プロセスは比較的環境に優しくない面がありますが、鋼管は非常に長期間使用でき、環境汚染に関する懸念もそれほど多くはありません。

私たちは複数の大手製鋼所と提携しており、すべての製品は出荷前に検査され、品質が保証されています。主な製品は各种の鋼管(ERW/SSAW/LSAW/镀锌/溶接鋼管/無継ぎ鋼管/ステンレス鋼管)、プロファイル(アメリカ標準、イギリス標準、オーストラリア標準 Hビーム鋼)、鉄筋、角鋼、平鋼、鋼板杭、各种サイズの鋼板や鋼巻、帯鋼、足場、鋼線、釘などです。

私たちは鋼管を溶接し、アメリカ/イギリス/オーストラリア基準のHビーム、日本の基準に従った鋼板杭の供給を行い、穴あけや切断などの深部加工サービスも提供しています。私たちの製品は西ヨーロッパ、オセアニア、南米、東南アジア、アフリカ、中東など多くの地域に輸出されています。

当社は鋼材輸出に17年の経験を持ち、多数のプロファイルやコイルを提供できます。また、輸出貿易に特化したグループがあり、迅速な見積りと最も適した溶接鋼管を提供可能です。私たちとの注文が増えるほど、価格はより安くなります!

私たちは非常に経験豊富な外貿チームを持っており、優れた製品知識、迅速な見積り、そして最高品質のサービスを提供します。専門家の営業チームは、溶接鋼管に関するあなたの質問や懸念にいつでも対応します。私たちはあなたにとって信頼できるビジネスパートナーであることを確信しています。