The corrugated pipes, essential for underpasses on highways and railways, feature a standardized design that promotes efficient, centralized manufacturing with a rapid production timeline. The installation process can occur independently, minimizing construction duration while reducing reliance on conventional building materials, thus enhancing environmental sustainability. Furthermore, these pipes can accommodate foundation deformation and distribute force effectively, mitigating risks associated with uneven settlement and protecting solid concrete structures against damage—especially in cold climates.

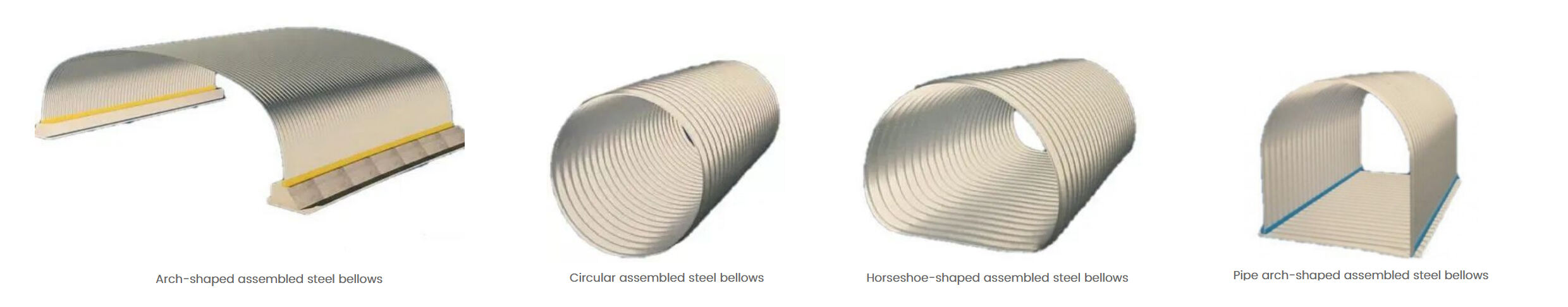

The assembled steel bellows come in various shapes: arch, circular, and horseshoe. Each variant serves specific engineering requirements.

Research indicates that properly treated steel bellows can achieve a service life exceeding 100 years, thanks to galvanization and specialized asphalt corrosion protection. The structure employs Q235-A hot-rolled steel plate, connecting multiple steel panels into a unified section, followed by longitudinal connection and molding. High-strength bolts (M 208.8 grade) and curved washers (HRC35 grade) secure the connections, while the hot-dip galvanized surface resists corrosion. Each culvert's foundation features a gravel bedding of 50-100 cm at 95% compaction, with M7.5 slurry masonry used for the hole filling. The water flow incline within the culvert typically measures 5%. Aside from the predominant shapes, the culverts also include elliptical and flanged types, with side slopes customizable for inlet and outlet design.

Application scope encompasses various scenarios:

- Rapid Passage Projects

- Hazardous Mountainous Roads

- Vehicle-Pedestrian Crossings

- High Fills in Mountainous Regions

- Frozen Grounds and Elevated Fills

- Shallow Fills for Livestock Access

- Urban and Field Conduits

- Agricultural Irrigation

- Heavy Hill Sites

- Deep and Shallow Frozen Grounds

- Coal Mine Caverns

- High Fill Areas in Wet Depressional Loess

- Replacement Solutions for Small Bridges

- High Fills on Saturated Loess with Low Bearing Capacity

Hot News

Hot News2024-09-05

2024-07-23

2024-06-14

2024-08-07

2024-05-23

2024-05-21