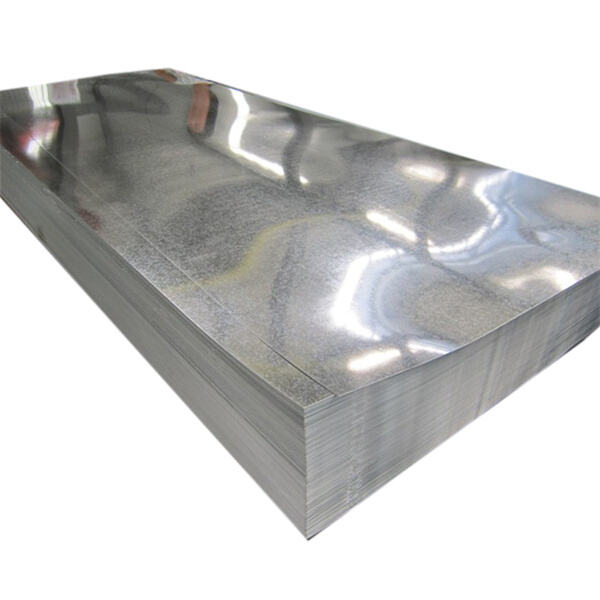

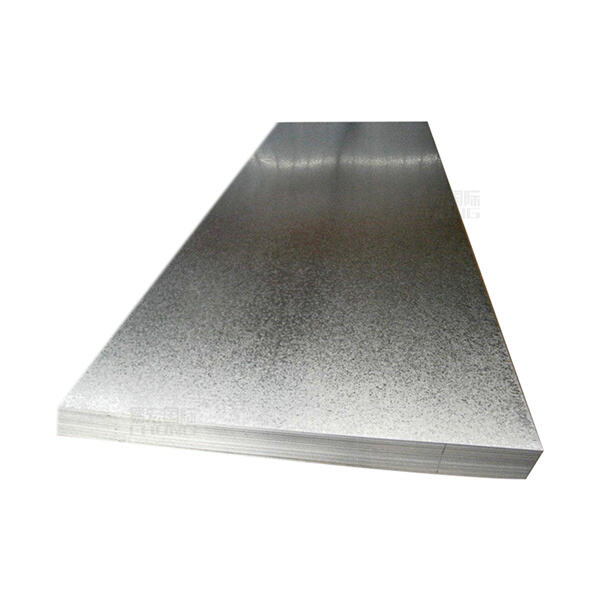

Yilokhu olungumthetho omphumeleyo wamatala etyeni ethileyo evela ukusetshenziswa emasipheni apho kuhlonishwa amanye amagama njenge-machines, amagumbi nokulula amasimu, yi-Galvanized Plate Steel. Ikhawulezi lokhu laphuma kwi-steel elincane ngokushesha kwindawo yokugcina kanti lokuhlola kakhulu. Leli metali elithile lavela ukukhethwa ngokukhoyo ngokusebenzela kumazwana wengcini ngokuthi lingcono kunye nokusetshenziswa emasipheni.

I-Galvanized Plate Steel uma kungena kakhulu kukho indlela yokuvumela okanye kokuthi lokulandelayo. Ukudlula kwisekhono esingabhedekileyo ngokushesha kuyinkulumo. Usihlobo wesihlobo sokuqinisekiswa njengesi steel eyahlukene ekubhedekanga nokungenwa nge-zinc yokuhlola. Lolu hlobo lokuhlola lokuxhasa kuhlola imetal ngu-reaction engeziwe ngazo isizatu sezikhatsi ezininzi. Lokhu kuhlanganisa amaxabiso akhe akudingekayo nokuhlola kwegama lakhe.

Ngokushesha kudala lokhu okungaphezulu kakhulu ngeesi-steel esisintu, i-Galvanized Plate Steel ingaphandle kwezinto zokugqibela ukusetshenziswa ngokwesobizo nokusebenzelo. Ucinga kuphela ngenxa yakho ukuba uyithemba kodwa le ncedo luyahlukile ngokwesikhashana esikhulu ngoba yindlela yakho yokuthi yasemva. Lokhu akuxhasa amaxesha angakho abanye abantu amali, kodwa kukhupha imali yesikhashana. Ngaba i-Galvanized Plate Steel ayahlatywa ngempumelelo, lokhu kuhlelisa ukuba yile ncedo eliphakamisekayo nokusetyenziswa kwesikhashana esikhulu.

Kunezinye zindlu eziningi lwezinyathelo zokuba i-Galvanized Plate Steel iyiphakamisi lokuncane kunoma imikhakha esiqinileyo nge-corrosion resistance. Isimo sokuqala sokuziphakama kwe-zinc layer nguqukethela ukuphinda ukubhubheka; yini, uyaphinda amadoda omkhulu nokufinyelela ukubhubheka kwabo. Ngokugcina, le ndaba yokulandelana nge-corrosive aspects ngokushesha kunoma umoya wemvula nokuthi uhlalelo lwesuntandavathi lalungiselela izinto ezingasusiweyo. Lolu hlobo lokuhlola kwe-Galvanized Plate Steel kulungisa isikati esidingeni ngokubona sikuphinde aphumelela ukususa.

I-Galvanized Plate Steel inakuthiwe ngokupheleleyo ngazo zonke iziphumo zesiyezi esikhundleni sentsha ngenqanawe yabo ngaphandle kwezimetalu eziningi. Ukusuka komsebenzi okuncane nokuhlola kwakhona, kusebenzisa lokhu lavela ukukhetha lokungcono emasipheni. Ngaphandle komhlaba, ngalokho olungcono lokusebenza i-Galvanized Plate Steel alingakwazi ukuhlala ngempela ngokusetyenziswa kukho imali engaphezulu. Ngalokho olungahlukeneyo, lokusebenza kunye nokunemisebenzi ekubeni ukufinyelela, leli metali elithile lavela isibonelo esisodwa somculo wesintshonalanga.

Siya iminyaka eyisibhenzi ekusasa kuhlanganiswa kwezistilwe nokuthi singakwazanga ukufinyelela umsindo omphambili wesitolo lesi. Ngakho esikhundleni, sithole isigaba somsebenzi wasekhaya esingahluhluke, nesivinini esihlabeleka, futhi singakwazanga ukubala amasolosheni okukhupheli kunye nezindaba eziphumaphuma. Ukuthi umbiko ubhede kakhulu, uphalazwi lokugcina kakhulu!

Siyakwamukela amagamni eziyindlebele ezilungileyo zokugcina Amerika/Britain/Australia, imibhalo yomgomo weH-ezilungileyo kwiseNihili, futhi siyethemba ukufakwa kwezinye izinto ezikhulu ngokushesha njengokubhala okanye ukupheka. Izinhlobo zakethu zithunyelwe eWestern Europe, Oceania, South America, Southeast Asia, Afrika, Middle East kunye nema-region eziyini.

Siyaziwa ngeminyaka emabili eyahlukileyo yezintaba ezilimi, futhi zonke izinhlela ezicingekayo zibhedlisele phambi kokuthumela, uhlobo olungaphakathi lungenziwe. Izinhlela ezikhoyo zonke izinto eziphakamisene nezintaba (ERW/SSAW/LSAW/ galvanized/rectangular pipe/seamless pipe/stainless steel pipe), amaparo (umkhondo wemali, umkhondo wobritish, Australian standard H-beam steel), amathathu, Angle steel, flat steel, steel sheet piles, izinsuku ezidingekileyo ezifanekiso nezinsuku ezinethunywa, strip steel, scaffolding, steel wire, imayiphi, nettling, nettles, nettles, nettles, nettles, nettles.

Uyihloniphe kakhulu amaphrofeshonali yomsebenzi wokuthengisela ngakwesobunxebo sokuphakamisa umoya, ukubuyekeza ngqukuze lwezikhatsi, ukuhlala nokungena imisebenzi yesikoste. Uyihloniphe kakhulu futhi umphathi wesayithi wokuhlola izifundo zokugcina, 24 izikhethe emasotini ethile lokusemthethweni, lokufinyelela noma lokususa. Siyiqinisekisi elibuzayo lokuthi siya kuhlonipha ngalo msebenzi.